News

Micro Laser Sintering Machine of the latest generation

Before the end of the year, we were able to put our fourth machine into operation.

With the Micro Laser Sinter machine of the latest generation, we are again expanding our machine park in order to build up further customer capacities and also to be able to offer more special materials.

In the meantime, the self-developed and constructed machine is fully integrated into the production process and contributes to providing our customers with more flexibility and even shorter delivery times.

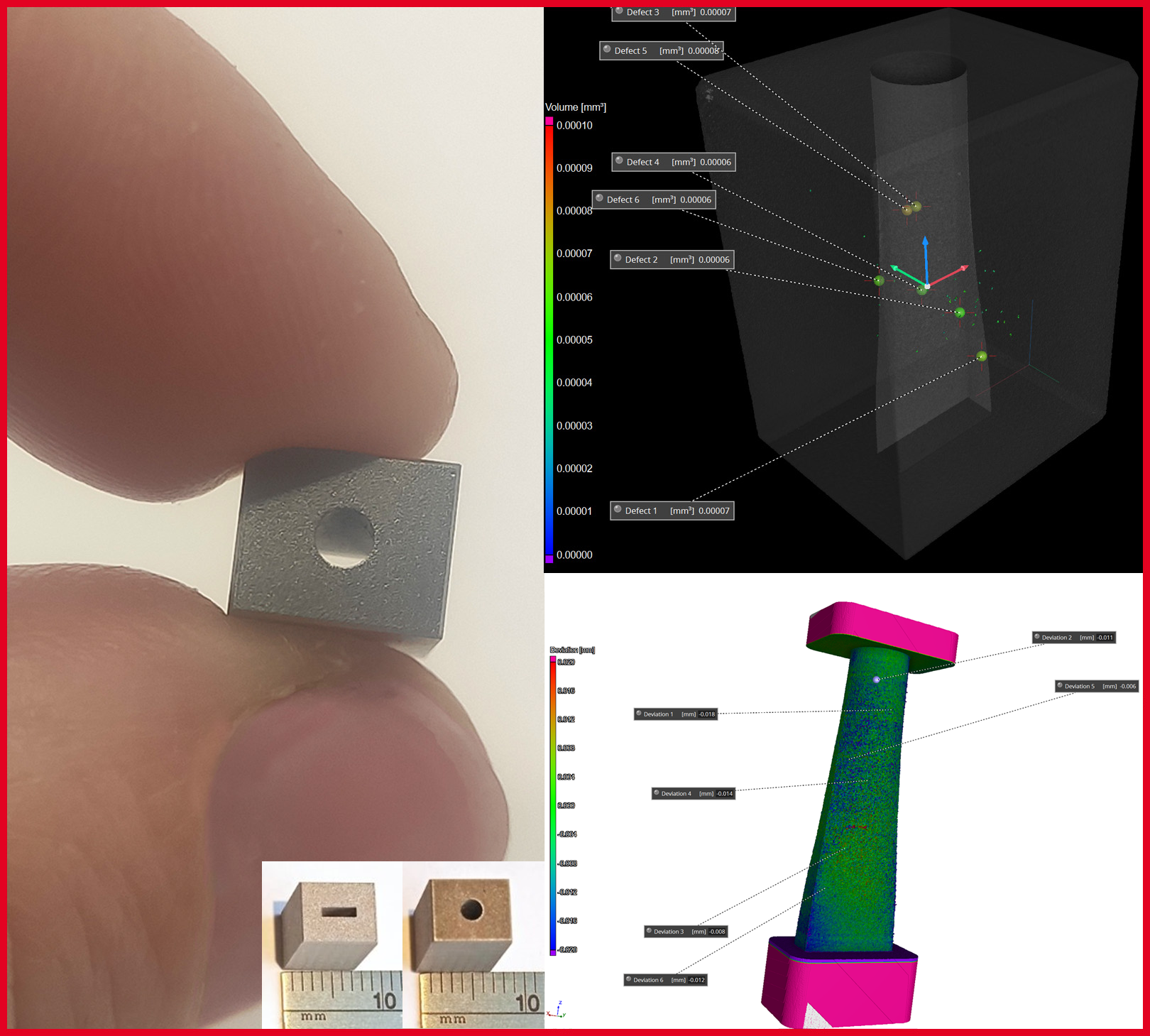

A complex shape and small dimensions part

On the picture is a customer application from the @Institute of Fundamental Technological Research IPPT Polish Academy of Sciences PAS (https://www.ippt.pan.pl/en/news/pasific-postdoctoral-fellowship-program). An innovative extrusion head for the 3D printing of continuous fiber reinforced thermoplastic polymer composites. The complex shape small dimensions part is meant to be the core of the polymer composite 3D printing extruder.

Lunch Chat

Join the next “Lunch Chat” of Swissphotonics and learn live everything important about the micro laser sintering of

3D MicroPrint GmbH as well as its application possibilities.

On Tuesday, 22.11.2022, at 12:00 – 12:45, Thomas Starke (Head of Development) will be available to answer your questions.

Register now for free under this link.

It's that time again: formnext opens ...

… its doors and gathers the world of additive manufacturing in the Frankfurt exhibition halls.

Meet the 3D MicroPrint team on site and let us inspire and advise you on the diverse possibilities of micro laser sintering.

Visit us from 15 – 18 November at stand B47 in hall 11.1 and learn more about the advantages of additive manufacturing in the µm range and possible applications for your company.

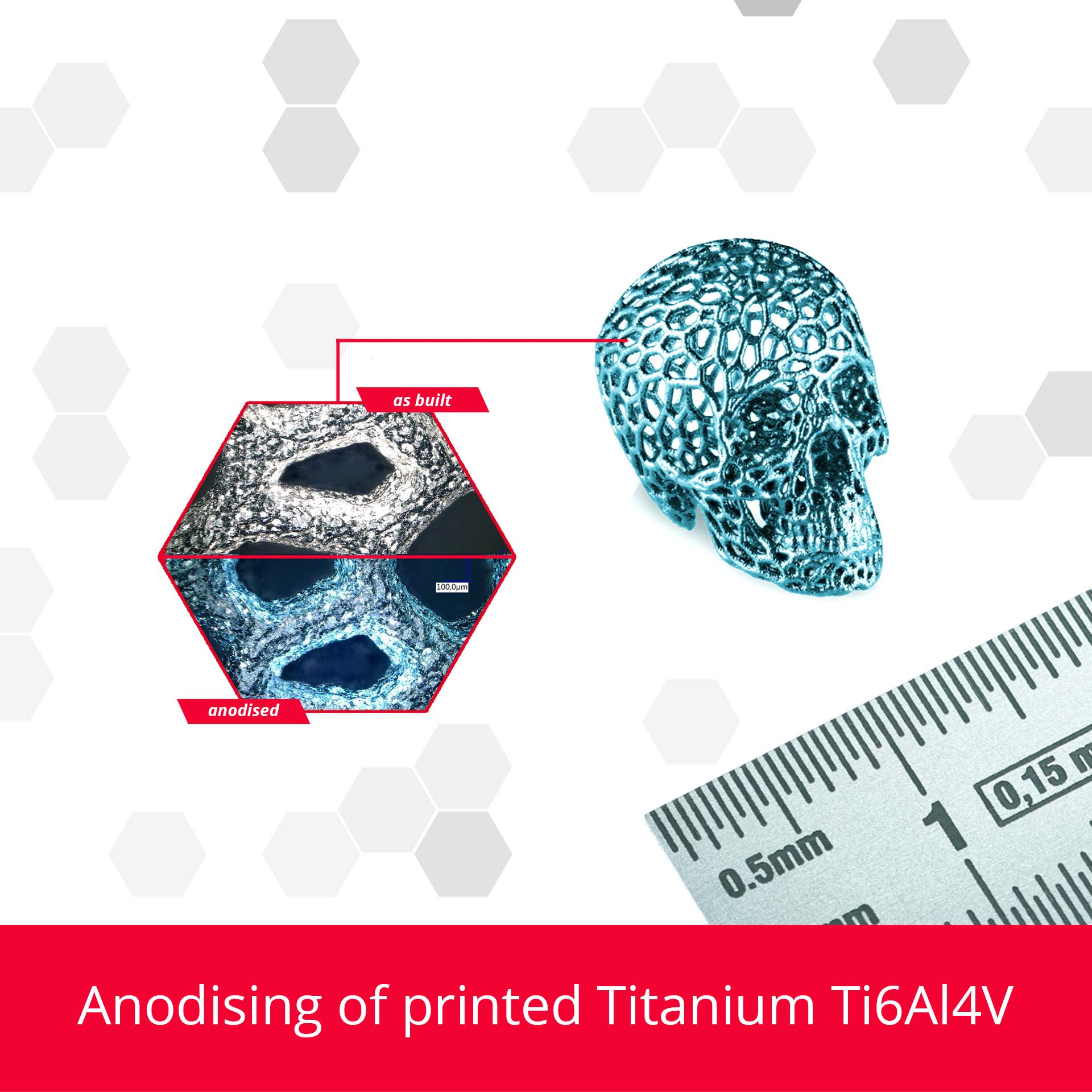

We present the great result of the cooperation with Titanex GmbH – micro laser sintering parts made of Ti6Al4V Grade 23 refined with Anodurit®.

Anodurit® is the Swiss innovation for true to size anodising of Titanium, Tantalum and Niobium.

The company Titanex is located in Gunningen (Southern Germany). This Swiss technology allows for custom anodising in colours (type 3) or even in grey and hard, known as type 2.

This particular crystalline oxide layer comes with a lower friction, avoids galling and enhances the corrosion resistance.

3D MicroPrint micro sample shown demonstrate the impressive surface effects created by the anodising process. Due to the metallically pure surfaces in as built condition the MLS printed parts retain their micro-roughness after anodising.

3D MicroPrint GmbH

3D MicroPrint GmbH